Fire protection in heavy vehicles used for mining places high demands on both the equipment and its durability. Such vehicles operate in the toughest of environments, constantly exposed to dust, vibrations, and extreme temperatures.

Johan Balstad, vice president of Sweden-based fire protection and rescue equipment supplier Dafo, sees fire protection as a crucial element for sustainable mining: “Fires in vehicles often have a very intense development and are difficult to extinguish with a portable fire extinguisher. With the right automatic fire suppression system, you get quick and effective protection that limits the consequences of a fire and gives vital time to evacuate.

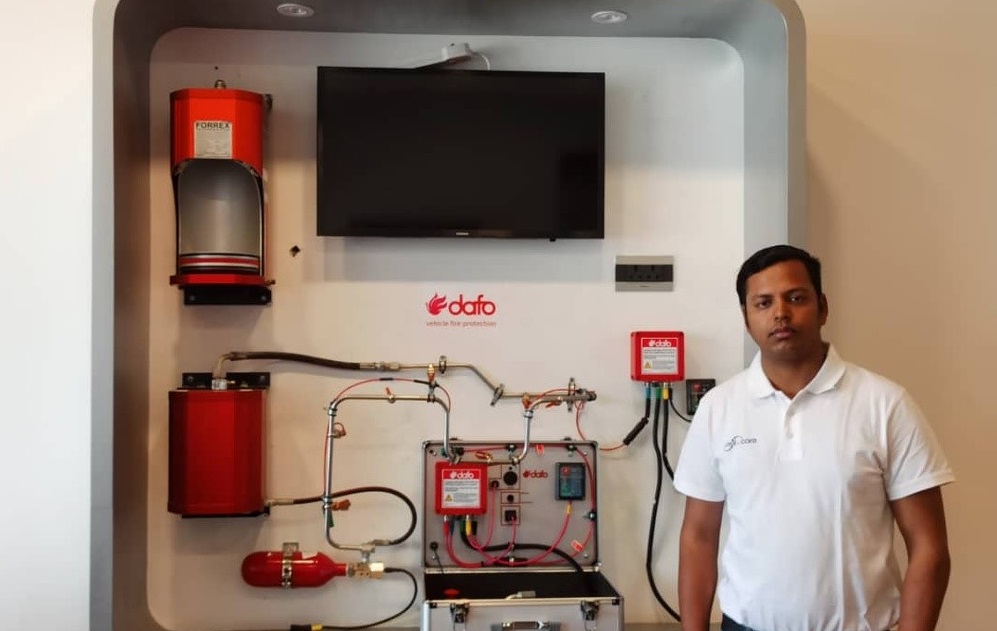

Dafo Vehicle Fire Protection offers a complete range of fire detection and fire suppression systems for heavy vehicles, buses, forestry machines, port cargo handling equipment, mining, and construction machinery.

“Dafo Vehicle Fire Protection experts are involved and assist in the design and planning of vehicles with manufacturers, to create well-integrated and efficient solutions. First of all, we want to eliminate or minimize the risk of personal injury. At the same time, we want to avoid downtime due to fires or other types of accidents, which in a mining environment can be problematic, costly, and time-consuming to rectify. Therefore, it becomes extra important that the systems and equipment work as intended,” says Balstad.

Extensive electrification in the mining industry is placing new demands on fire protection for electric equipment. A battery that catches fire through thermal runaway is not the same as fires in diesel or gasoline-powered vehicles.

Dafo has launched a fire protection system for electric and hybrid vehicles that is activated before a fire in a battery occurs. The fire protection solution has been developed for buses but will also be available for other heavy electric vehicles.

Anders Gulliksson, technical manager, Dafo Vehicle Fire Protection, says: “Low, or non-existent emissions, cost-efficient operation, and reduced noise levels are some of the major advantages of hybrid and electric vehicles today, but the disadvantages of the technology when something goes wrong are less known. Fires in lithium-ion batteries of electric vehicles usually have rapid progress and are very difficult to extinguish. Dafo was concerned early on regarding the potential fire risks and dangers this technology would bring, which meant that we also started looking at solutions to meet the development.”

Dafo’s patented suppression system was developed through the EU-funded research project Li-IonFire and initially aimed at electrified buses in public transport.

“Our system is an advanced fire suppression system with a fire prevention part integrated into the system. This means that the system can detect any temperature changes in the lithium-ion battery at an early stage and cool it down before reaching the critical ‘thermal runaway’ state, which can result in the battery starting to burn and a fully developed fire occurs,” says Gulliksson.

However, no methods have been successful yet in extinguishing a battery that has already caught fire and entered the thermal runaway stage, after an overcharge or vehicle collision. If the battery starts to burn, the highly toxic gas emits hydrogen fluoride (HF), which can cause serious damage to both the skin and the respiratory tract.

“The new Li-IonFire fire protection system will detect potential battery failure, at the earliest possible stage and take immediate action by spot cooling, using the suppression agent Forrex EV. This will effectively stop, or delay, a potentially hazardous situation without the fire developing further,” says Gulliksson.